Leo company's product prototype.

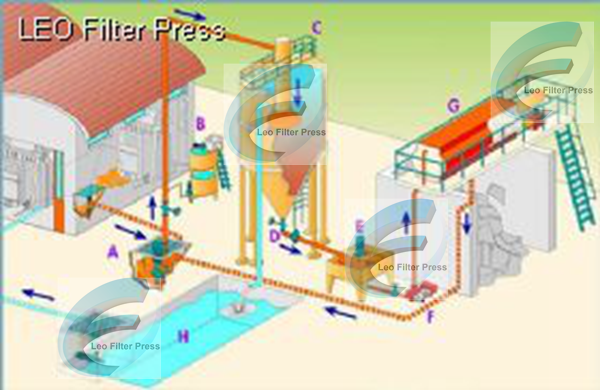

Wastewater Pre-treatment Before Going to Filter Press for Filtering Operation

Wastewater Treatment(Thickening or PH Adjustment )Before Filter Press Operation

Today,when we browsing the pages,we found a piece of news from a forum,a guy facing a problem for flocculate the wastewater,according to our judging,the wastewater maybe from painting,and they are trying to install a filter press to filter those wastewater,but there is zinc containments,the problem is the wastewater can't be treated to be thickened,and still have a problem to flocculate it to below 3ppm,if so,it will likely require a wastewater pretreatment stage to improve filter press performance, probably some sort of surfactant.If not,there will be a problem for using filter press for wastewater dewatering.

And if can't adjust the painting wastewater to better conditions,then the filter press can't be reponsible for the using result such as no formation for cake,bad using conditions and design failure etc.

But how to get thickened wastewater,we can add flocculant agents such as PAM,PAC,to adjust the condition of the wastewater,or add chemical agent to adjust its PH value,but some other engineers are suggesting using RO membranes first,as RO membranes are capable of reducing COD in Latex Paint from 50,000 mg/L to 250mg/L in the filtrate from one pass.But if so,the solid content become much more fewer than before,the filter press filtering plan will be spoiled completely.

Maybe buid tanks for thickening and adding floculant agents will be a helpful method for this wastewater treatment.

There are several methods for wastewater thickening:

1. thicken by gravity,also called gravity thickener

this machine will use solid and liquid gravity difference directly to fulfile thickening result.when we are facing tinny solid size material filtering,for example only severial micron,in ordeer to increase filtering speed,we will thicken the material first,that is,let them to build bigger bulks and make them to form groups to increase filtering efficiency

the gravity thickner have two types,continuous and batch working ones

2. high efficiency thickner

this machine will work with flocculant agent together to thicken the wastewater in high efficiency

3.cyclone

this machine design based on inertial centrifugal force by cylinder high speed movement,a big some of filtrate will be discharged from upper discharging port and the thicken suspension will be discharged from lower port,the cyclone works base on inertial centrifugal force not material gravity,so it can be installed in any place and degree

Hangzhou Leo Filter Press Co.,Ltd.

Hangzhou Leo Filter Press Co.,Ltd.